Model Name | Feeder Size (Width mm x Length mm) | Maximum Feed Size (mm) | Throughput Capacity (TPH) | Required Power (KW / HP) | Type Of Vibrator | Download Brochure |

VGF 1036 | 1000 x 3600 | 500 | 150 | 7.4 (3.7 x 2) / 10 (5 x 2) | Linear Electrical | |

VGF 1040 | 1000 x 4000 | 500 | 150 | 7.4 (3.7 x 2) / 10 (5 x 2) | Linear Electrical | |

VGF 1240 | 1200 x 4000 | 600 | 200 | 7.4 (3.7 x 2) / 10 (5 x 2) | Linear Electrical | |

VGF 1540 | 1500 x 4000 | 750 | 300 | 11 (5.5 x 2) / 15 (7.5 x 2) | Linear Electrical | View Details |

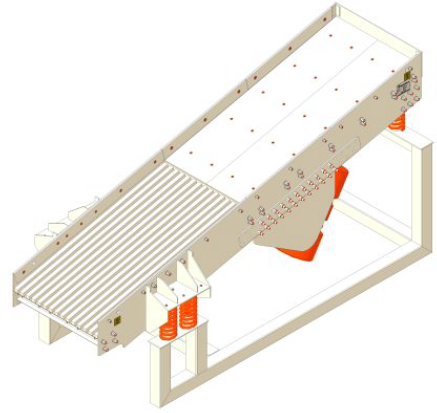

Vibratory grizzly feeders are commonly used in the mining and quarrying industries to feed crushers, conveyors, and other equipment. They are essentially heavy-duty vibrating screens that are designed to withstand the toughest conditions and handle large quantities of material. In this article, we will discuss the advantages of vibratory grizzly feeders, their working principle, and the components that make up a typical feeder system.

Advantages of Vibratory Grizzly Feeders

Efficient Material Handling: Vibratory grizzly feeders are highly efficient in handling a wide variety of materials, including bulky and abrasive materials such as ore, gravel, and rock. They can handle large quantities of material and distribute it evenly across the width of the feeder.

Customizable Settings: Vibratory grizzly feeders can be customized to suit specific applications. They are available in different sizes and configurations to accommodate different types of material and feed rates. The amplitude and frequency of the vibrations can also be adjusted to control the flow of material.

Low Maintenance: Vibratory grizzly feeder are equipped with vibrating assembly of twin vibratory motor, minimizing the dependable and maintenance part or assembly, which makes it more reliable and low maintenance to operate. They are made from heavy-duty materials that can withstand harsh conditions, and their simple design makes them easy to operate and maintain.

Increased Productivity: Vibratory grizzly feeders can help increase productivity by reducing downtime and improving efficiency. They can handle large volumes of material and distribute it evenly, which helps prevent clogs and jams in downstream equipment.

Working Principle of Vibratory Grizzly Feeders

A vibratory grizzly feeder consists of Feeder body (a pan or trough combined with grizzly section) that is mounted on a set of springs and is vibrated by dual electric vibrating motor. The vibration causes linear moment of feeder body, which provide the linear motion to the fed material and grizzly separates the unwanted quarry waste material, and only the clean material is fed into a crusher or other downstream equipment.

Vibratory grizzly feeders are an essential component of many mining and quarrying operations. They are highly efficient in handling a wide variety of materials, customizable to suit specific applications, and require minimal maintenance. By using a vibratory grizzly feeder, operators can improve efficiency, reduce downtime, and increase productivity.

© 2023 Maxwell Crushtech. All rights reserved

Developed By India Online Business Solutions.