| Model Name | Cone Diameter (mm) | Maximum Feed Size (mm) | CSS Range (mm) | Throughput Capacity (TPH) | Crusher Pulley RPM | Required Power (KW / HP) | Download Brochure |

| GC 0820 | 820 | 120 | 22-28 | 75-110 | 1015 | 75/100 | View Details |

| GC 0975 | 975 | 150 | 15 – 26 | 90 – 155 | 1015 | 110 / 150 | View Details |

| GC 1080 | 1080 | 200 | 18 – 30 | 120 – 200 | 1015 | 180 / 240 | View Details |

| GF 0820 | 820 | 90 – 155 | 120 – 200 | 1080 | 50 – 80 | 75 – 130 | View Details |

| GF 0975 | 975 | 60 | 6 – 15 | 75 – 130 | 1015 | 110 / 150 | View Details |

| GF 1080 | 1080 | 75 | 8 – 20 | 110 – 175 | 1015 | 180 / 240 | View Details |

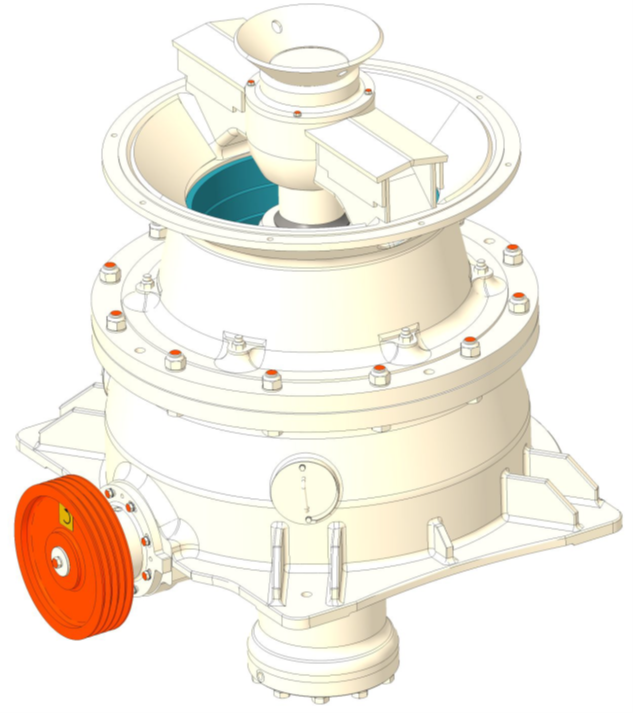

Maxwell G type Cone Crusher is advance and robust technology in the world. Due to proven and optimized design , it provides high efficiency, strong crushing force, high yield and low operation cost.

Due to large feed size, it can be adapted to various crushing applications, saving for the capital investment. Change in stroke and multiple cavity option makes it useful for different purposes.

Compact yet robust top bottom frame design with shaft support at both ends makes a robust solution for crushing the hard stones.

Maxwell GF type cone is equipped with short head cone for fine crushing.

Maxwell GC type cone is equipped with standard head cone for coarse crushing.

Maxwell G type Cone crusher are equipped with Hydraulic System for CSS Adjustment. Easy removal of clogged material inside the crushing chamber by hydraulic lowering system. Fan Cooled External oil circulation system provides stable oil supply to the machine. Oil Circulation system can be interlocked with main motor for additional safety. The Hydraulic Piston supported shaft protects the machine against the uncrushable material by lowering the shaft.

A cone crusher is a type of crushing equipment used in mining, quarrying, and construction industries. It is designed to crush a variety of materials to a specific size and shape, including stones, rocks, and ores. Cone crushers are often used as secondary or tertiary crushers in crushing circuits, where they can reduce the size of the feed material to a more manageable size for further processing.

The cone crusher consists of a mantle and a concave, both of which are wear-resistant liners made from manganese steel. The mantle is mounted on a vertical shaft, which is supported by bearings at the top and bottom of the shaft. The concave is fixed to the top of the crusher frame.

Cone crushers are available in various types and sizes, each with unique features and benefits. Some of the most common types of cone crushers include the spring cone crusher, hydraulic cone crusher, and Symons cone crusher.

G type Cone Crusher is a very compact design with Top and Bottom frame bolted together. The Main Shaft is Vertically mounted with support at top and bottom. The Main Shaft gets gyration motion due to eccentric rotation. The Mantle is with fixed to Main shaft assembly, Thus Mantle gets Gyration Motion and material is gets crushed inside the Cavity form between Mantle and Concave. Concave is fixed with Top Frame.

G Type Cone Crusher is new, compact and versatile design with variety of cavity and stroke option to cater the need. The High pivot point make it more effective with rough and flaky material.

Cone crushers offer a number of advantages over other types of crushing equipment. Some of these advantages include their ability to produce a more uniform product size, reduce the amount of fines generated during crushing, and offer a high degree of reliability and durability. Cone crushers are also ideal for use in a wide range of applications, including mining, quarrying, and construction.

Cone crushers are composed of various parts that work together to achieve the desired crushing outcome. Some of the key components of a cone crusher include the mantle, concave, Main Shaft, eccentric and spider bearing. These parts are essential for ensuring the efficient and reliable operation of the crusher.

Cone Crusher Maintenance Regular maintenance is essential for the proper functioning of a cone crusher. This includes regular inspection of the machine to ensure that all components are in good working condition, and that any worn or damaged parts are replaced in a timely manner. It is also important to ensure that the crusher is operated within its design parameters, and that the recommended lubrication and maintenance procedures are followed.

In conclusion, cone crushers are an essential piece of equipment in the mining, quarrying, and construction industries. They are designed to crush a variety of materials to a specific size and shape, and offer a number of advantages over other types of crushing equipment. When selecting a cone crusher, it is important to consider factors such as the type and size of material being crushed, the desired product size, and the operating conditions of the crusher. Regular maintenance is essential for ensuring the long-term reliability and efficiency of the machine.

© 2023 Maxwell Crushtech. All rights reserved

Developed By India Online Business Solutions.