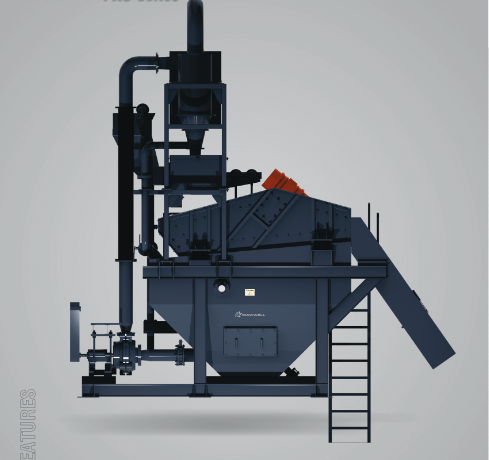

Washing Plant PRO Series

SALIENT FEATURES

- High performance de-watering screen equipped with long-life

- PU mesh & reliable vibratory motors

- Proven cyclone design assures fine removal, PU lined cyclone gives longer durability

- Multi-function single point water inlet provides ease of installation and maintenance

- Slurry distribution at overhead tank for ease of maintenance of discharge line

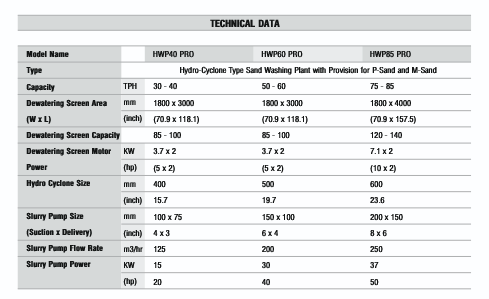

Capacity is based on 15% fines in feed material of crush sand. Capacity varies due to feed material particle size gradation. Capacity indicates maximum capacity of total slurry including water and sand. Capacity depends on the type of material, plasticity, gradation, and general flowability

of the material. Capacities are reduced considerably when handling coarse or sticky material.

Note: The information, including construction and technical details, is subject to change without prior notice. For the latest information, please contact us.

Advanced Sand & Aggregate Washing

The PRO Series Washing Plant ensures efficient removal of silt, clay, and other impurities from sand and aggregates. It enhances material quality and supports higher-grade output for construction and infrastructure use. Built with cutting-edge technology, it minimizes water usage and operational cost. Ideal for river sand, crushed stone, and manufactured sand applications. Boosts profitability through cleaner and market-ready materials.

Modular & Scalable Design

Designed for flexibility, the PRO Series offers modular configurations to suit varying production needs. Easy integration with existing crushing setups ensures smoother operations. Each unit is engineered for quick setup, expansion, and relocation. Supports both small-scale and large-capacity washing requirements. Scalable for future upgrades and output increases.

High-Efficiency Dewatering Screens

Integrated with high-performance dewatering screens to ensure faster drying and better water recovery. Reduces moisture content to improve material handling and storage. Increases the efficiency of downstream processes like stacking and loading. Rugged design ensures consistent performance in tough site conditions. Low maintenance and long operational life.

Robust Build for Harsh Environments

Engineered with heavy-duty materials to withstand demanding mining and quarry conditions. Corrosion-resistant components enhance durability and reduce wear. Performs reliably in wet, dusty, and abrasive environments. Ensures continuous operation with minimal downtime. Built to meet industrial-grade safety and quality standards.

Reference

- Maxwell’s Washing Plant PRO Series is a trusted choice across multiple industries for efficient sand and aggregate washing.

- Designed with advanced hydrocyclone technology, it ensures high-quality output with minimal water usage.

- Clients rely on its consistent performance, easy maintenance, and modular design for seamless integration.

- The PRO Series is widely used in real-world projects, delivering reliable results in challenging site conditions.

- With successful installations across India, it stands as a benchmark in washing efficiency and durability.

- Maxwell’s commitment to innovation and customer satisfaction is reflected in every PRO Series reference.

Description

The Maxwell PRO Series Washing Plant is a cutting-edge solution engineered to deliver maximum efficiency and performance in material washing and classification. Designed with precision and built for reliability, the PRO Series is tailored to meet the rigorous demands of modern mining, quarrying, and construction industries. Whether it’s the removal of silt, clay, or unwanted fines from aggregates, this plant ensures consistently high-quality output through advanced washing techniques.

At the heart of the PRO Series is an intelligently integrated system that combines a high-capacity feed hopper, efficient conveyors, hydrocyclones, vibrating screens, and dewatering solutions—all streamlined for optimal performance. Its modular design allows for flexibility in configuration, enabling it to be easily adapted for a variety of applications, including sand, gravel, crushed stone, and manufactured sand processing.

The PRO Series features a fully automated control system, ensuring user-friendly operation with minimal manual intervention. Smart sensors and real-time monitoring help maintain optimal water flow, material separation, and energy consumption. Its robust construction, using corrosion-resistant components and heavy-duty frames, ensures long-term durability even in the most challenging environments.

Maxwell’s commitment to innovation is reflected in the PRO Series’ eco-friendly design. With efficient water recycling systems and minimal energy usage, this plant supports sustainable operations without compromising productivity. The enhanced dewatering capabilities reduce moisture content, making your final product more market-ready and transport-efficient.

Safety and ease of maintenance are at the core of the PRO Series. The plant includes strategically placed platforms and walkways, as well as accessible service points for filters, pumps, and motors. All moving parts are enclosed or guarded, complying with international safety standards to protect operators and technicians.

What sets the Maxwell PRO Series apart is its unmatched scalability. Whether you’re a small-scale producer or a large commercial operation, the plant can be scaled up or down based on your specific capacity requirements. Optional add-ons such as dual washing decks, customized cyclones, and automatic sludge management systems offer unparalleled customization.

Designed and manufactured in India with global quality standards, the PRO Series Washing Plant has already proven its worth across numerous installations nationwide and internationally. Its ability to process multiple feed types with consistent accuracy makes it a reliable backbone for any washing and classification workflow.