India Best Crusher Manufacturing Industires

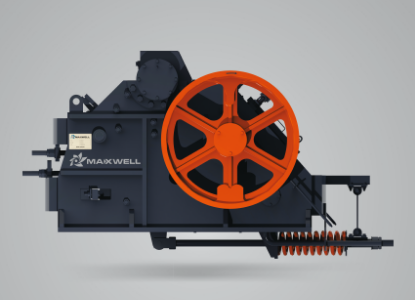

Maxwell Crushtech is a leading manufacturer of comprehensive crushing and screening solutions, delivering high-performance equipment engineered for durability and precision.

About

Maxwell Crushtech

Vast Industry Experience Since 1989, Professionals at Maxwell Crushtech made it one of the noted Exporter, manufacturer, Service Provider and Supplier of state-of-the-art Stone Crushers, Jaw Crusher, Cone Crusher, Grizzly Feeder, Vibrating Screen, Horizontal Shaft Impactor (HSI), Vertical Shaft Impactor (VSI), Sand Washing Unit, Crusher Plant, Sand Washing Plant etc.

We are given strong backup support by a team of sincere engineers which motivates us to take another step ahead in the direction of manufacturing high quality products. No stone is left unturned by us, as far as technology upgradations and manufacturing technicalities are concerned. We take all the necessary initiatives at every level of production process to ensure that top notch quality remains an inherent part of our affairs. The company endeavors to maintain competitive price and stick to prompt delivery norms. We also provide OEM service both at our workshop and at site.

Research & Development

Our manufacturing program lead to produce Quality product with lower cost and reliable performance.

Additional Services

Extended warranty support of trained manpower, parts & operation.

Make in India

First Indian manufacturer with 100% in house technology & sourcing.

24x7 Support

Service & Parts availability with stock points.

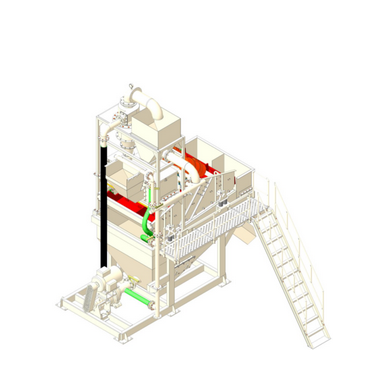

Maxwell offers end-to-end crushing and screening solutions engineered for efficiency, durability, and superior material processing performance.

Maxwell delivers high-efficiency production solutions through advanced crushing and screening systems designed for maximum output and reliability.

Get expert guidance with a Free Consultation from Maxwell – your trusted partner in comprehensive crushing and screening solutions.

Manufacturer of Crushing & Screening equipments

Maxwell Crushtech a customer centric company offers quality Crushing & Screening products and services. Our mission statement is consistency in customer satisfaction with superior quality products & prompt after sales service.

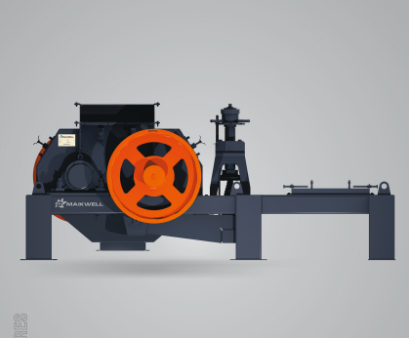

The Dynamic design of New single toggle jaw crusher promises efficient engineered product with massive

Highly efficient design delivers maximum performance as compared to other competitive manufacturers.

Maxwell S type cone crusher is proven Symons Technology crusher with most efficient and economical production

Maxwell G type cone crusher is world renowned and pioneer technology in the world. Due to proven

Vertical Shaft Impactor (VSI) is a type of crusher that works on Impaction to reduce the size. Mainly it is used for reduction in flakiness or fine material generation.

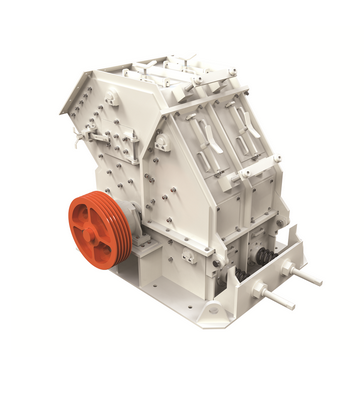

The working principle of an HSI crusher involves the use of impact to crush materials. It has larger feed size and works very well with medium hard to soft material

This product is widely used for making various kinds of mine, such as cement, fire-proof materials

High Performance De-watering screen equipped with lonng life PuMesh & Reliable Vibratory Motors

A Single Shaft Grizzly Feeder is a heavy-duty machine used in mining and quarrying to uniformly feed large materials into crushers or screens.

A Double Shaft Grizzly Feeder is a rugged machine used in mining and quarrying to evenly feed large materials into crushers or screens. It has two counter-rotating shafts.

A Vibratory Grizzly Feeder is a machine used in mining and construction to evenly and continuously feed materials into crushers or screens through vibration.

A Pan Feeder is a machine used in material handling to uniformly feed bulk materials into a process, such as a conveyor, crusher or screen.

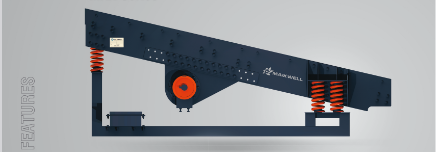

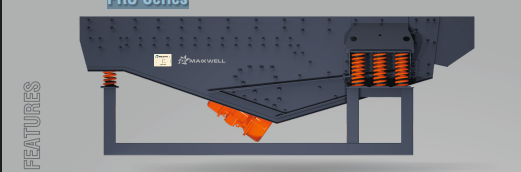

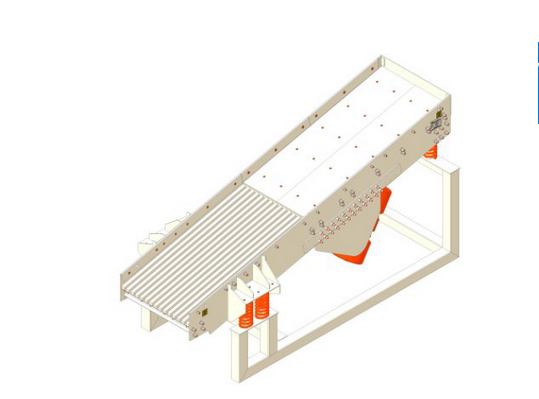

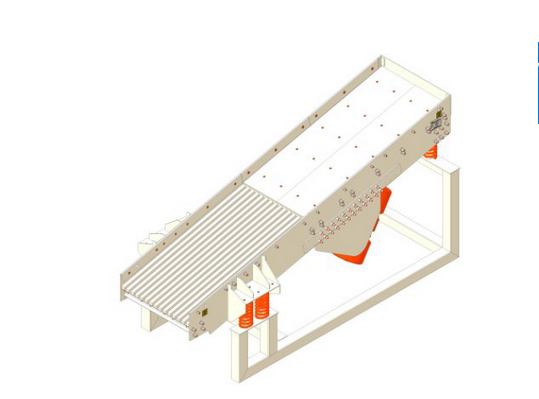

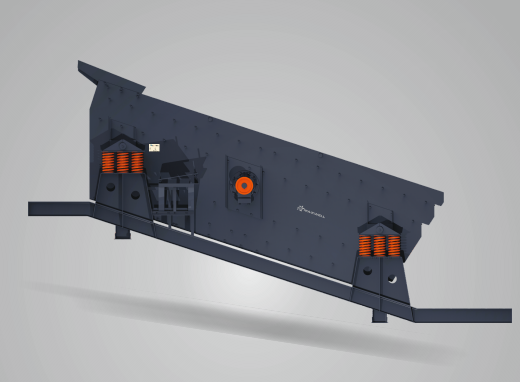

Vibrating screen for stand alone or multiple installations are manufactured in a wide range of sizes

Belt Conveyor are used for conveying material from one point to the other. It is widely used in different application for material conveying.

Radial Stage Conveyor are special purpose conveyors where in the Conveyor can be redial moved with respect to the tail drum (Feed Point), increasing the stack area at head drum (Discharge Point)

WHY CHOOSE US

Maxwell Crushtech is a reputable company specializing in the design, manufacture, and supply of high-quality crushing, screening, and material handling equipment. With years of experience and expertise, we offer innovative solutions, excellent customer service, and a commitment to exceeding our clients’ expectations. Our products are reliable, efficient, and cost-effective, and we strive to ensure customer satisfaction at all times. Choose us for your crushing and screening needs, and experience the difference!

Who we are

We Are The Leading Industrial Factory In The World.

We are the leading industrial force behind world-class crushing and screening solutions, setting global benchmarks in performance, innovation, and reliability.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Explore our expert resources for in-depth knowledge, product guides, and technical support in crushing and screening solutions.

Analyze every stage of your crushing and screening process with Maxwell’s smart solutions to ensure optimal performance, efficiency, and output quality.

Maxwell delivers target-oriented crushing and screening solutions designed to maximize productivity and meet precise material specifications with efficiency and precision.

Maxwell ensures transparent processes and clear communication at every stage, building trust through integrity in crushing and screening solutions.

Delivering uncompromised quality through precision-engineered crushing and screening solutions built to exceed industry standards.

Maxwell stands as a prestigious name in comprehensive crushing and screening solutions, trusted for innovation, quality, and performance across industries.

Maxwell prioritizes environmentally responsible solutions by integrating energy-efficient technology and water-saving systems across its crushing and screening operations.

We treat every client interaction and project detail as strictly confidential, ensuring complete trust and data security at Maxwell Comprehensive Crushing & Screening Solutions.

Experience uninterrupted operations with Maxwell’s 24/7 premium support, ensuring expert assistance anytime you need it.

Join our community of satisfied industrial customers.

Join our growing community of satisfied industrial customers who trust Maxwell for reliable and high-performance crushing and screening solutions.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

How it works

When you need experience, we have it covered.

When you need experience, Maxwell delivers—with decades of proven expertise in comprehensive crushing and screening solutions.

Consultation what you need.

Get expert consultation tailored to your specific crushing and screening needs with Maxwell’s industry-leading solutions.

Create a contract for work.

Create a clear and professional work contract with Maxwell to ensure transparency, project alignment, and seamless execution in crushing and screening solutions.

Production the item

Efficiently engineered for high-output performance, Maxwell ensures precision-driven production of every crushing and screening component to meet industry demands.

Quality control before delivery

We ensure strict quality control checks before delivery to guarantee that every Maxwell Crushing & Screening solution meets the highest performance and durability standards.

Trusted by 25,000+ world-class brands and organizations of all sizes.