Model Name | Feeder Size (Width mm x Length mm) | Maximum Feed Size (mm) | Throughput Capacity (TPH) | Required Power (KW / HP) | Type Of Vibrator | Download Brochure |

MGFDS 1240 | 1200 x 4000 | 600 | 200 | 22 / 30 | Linear Mechanical | |

MGFDS 1540 | 1500 x 4000 | 750 | 300 | 30 / 40 | Linear Mechanical |

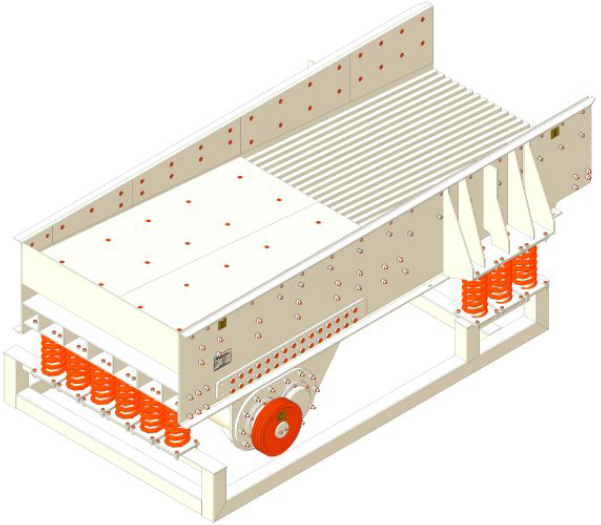

A double shaft grizzly feeder is an essential piece of equipment used in mining and quarrying operations. It is designed to receive and control the flow of large rocks and other materials from a primary crusher or conveyor belt system. The Grizzly feeder’s primary function is to separate the quarry waste (smaller particles) from the larger ones and direct the latter to the crusher or conveyor for further processing.

Double shaft grizzly feeders are heavy duty grizzly feeder equipped with vibration unit of two eccentric shafts that are connected by a set of gears. These gears allow the two eccentric shafts to rotate in opposite directions, which causes a linear motion of the material to be evenly distributed across the width of the feeder. The feeder is also equipped with a set of heavy-duty bars or grizzly bars that are designed to filter out quarry waste from the larger rocks and other materials, allowing only clean material entering the further crushing circuit.

The design of a double shaft grizzly feeder is critical to its performance. The feeder must be able to withstand the harsh conditions of the mining and quarrying industry, including high temperatures, dust, and heavy loads. The materials used in the construction of the feeder, such as the grizzly bars, must also be able to withstand the wear and tear of the materials passing through the feeder.

Grizzly feeders are available in a range of sizes and capacities to meet the needs of different applications. The size of the feeder is determined by the size of the rocks and capacity needed. The capacity of the feeder is determined by the speed of the shafts and stroke of eccentric mechanism.

Advantages of Double Shaft Grizzly Feeder:

Efficient Material Handling: Double shaft grizzly feeders are designed to efficiently handle large rocks and other materials, which helps to reduce the amount of manual labor required for material handling.

Uniform Feeding: The use of gears in a double shaft grizzly feeder ensures that linear vibration , which helps to ensure a uniform feeding process.

Reliable Operation: Double shaft grizzly feeders are heavy duty feeders, designed to operate reliably in harsh environments, which helps to minimize downtime and maintenance costs.

Versatile: Double shaft grizzly feeders can be used in a range of applications, including mining, quarrying, and construction.

In conclusion, a double shaft grizzly feeder is an essential piece of equipment for any mining or quarrying operation that requires the efficient handling of large rocks and other materials. The design of the feeder is critical to its performance, and it must be able to withstand the harsh conditions of the industry. With its many advantages, the double shaft grizzly feeder is a versatile and reliable option for a range of applications.

© 2023 Maxwell Crushtech. All rights reserved

Developed By India Online Business Solutions.