| Model Name | THROUGHPUT CAPACITY (TPH) | ROLLER WIDTH (mm) | ROLLER DIAMETER (mm) | Download Brochure |

| SDRC 0808 | 20 – 30 | 800 | 800 | View Details |

There are many other models available with Change of Roller Diameter with Rotor Width as per user requirements. The models are, in general, have following technical specifications:

THROUGHPUT CAPACITY (TPH) : 10 – 80

ROLLER WIDTH (mm) : 400 – 1000

ROLLER DIAMETER (mm) : 400 – 1000

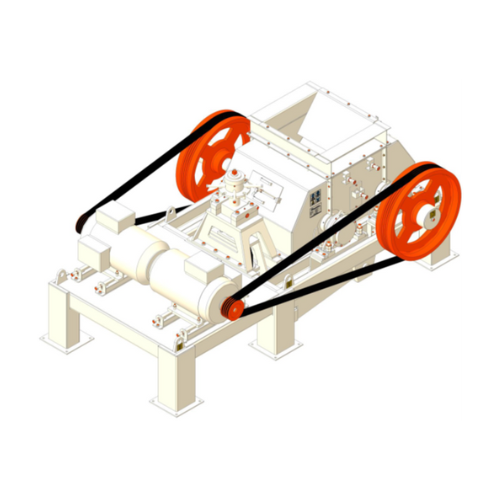

The design of Smooth Double Roller Crusher is robust to cater the customer need. It has the reliable and easy CSS Setting through square threaded Jack System. Roll fitting is through tapered casted hub ring. Heavy-duty bearing pedestal with ease of operation.

The Maxwell Smooth Double Roller Crusher has very easy and accurate CSS setting through Square threaded Jack without insertion of Sims or any additional part usage. The Roll change is easy as it is locked with tapered locking hub ring.

The fully machined roll and tapered locking system delivers troubled free performance. Reliable material usage of shaft and proven performance of bearing gives consistent performance. The specially designed volute spring eliminated any crushing shocks with unified crushing size.

Roll crushers are commonly used in the mining industry for the crushing of rocks, ores, and other materials. They are designed to work in tertiary stage to produce more fine materials. In this article, we will discuss the various aspects of roll crushers, including their design, parts, advantages, types, and working principle.

Roll Crusher Design: A roll crusher consists of a twin heavy cylindrical roll-cells that are mounted on two parallel horizontal axes. The roll-cells rotate in opposite directions and are driven by a belt or a set of gears. The gap between the roll-cells can be adjusted to control the size of the crushed material. Roll crushers are typically designed to handle materials that are soft to hard, such as coal, limestone, phosphate rock, aggregate, basalt and fertilizer.

Roll Crusher Parts: The main components of a roll crusher include the frame, roll-cells, bearings, Gap setting mechanism and drive system. The frame is made of welded or cast steel and provides support for the roll-cells. The roll-cells are mounted on the frame and rotate in opposite directions. The bearings support the rollers and allow them to rotate freely. The Gap setting mechanism allows to set the gap between the rollers to decide the size of crushed material. The drive system consists of a motor, gears, and a belt or chain that connects the motor to the roll-cells.

Roll Crusher Advantages: Roll crushers offer several advantages over other crushing equipment. They are compact and require less space than other crushers. They are also easy to install and maintain, and their simple design makes them reliable and efficient. Roll crushers are also versatile and can be used for a variety of applications, such as crushing coal, limestone, and minerals.

Roll Crusher Working Principle: The working principle of a roll crusher is based on compression. The material is fed between the roll-cells, and the roll-cells rotate in opposite directions. As the roll-cells rotates, it compresses the feed material together, and eventually the material is crushed into smaller pieces. The size of the crushed material depends on the gap between the roll-cells and the feed size depends on diameter of the roll-cells.

Roll crushers are a popular choice for many industries, including mining, construction, and recycling. They offer a reliable and efficient way to crush materials, and their simple design makes them easy to operate and maintain. The length of the roll-cells will decide the production capacity whereas diameter of the roll-cells will decide the feed size, thus there are many different models available with Diameter and Length Combination.

Regular maintenance is essential for the proper functioning of a roll crusher. This includes regular inspection of the machine to ensure that all components are in good working condition, and that any worn or damaged parts are replaced in a timely manner. It is also important to ensure that the crusher is operated within its design parameters, and that the recommended lubrication and maintenance procedures are followed.

In conclusion, roll crushers are an essential piece of equipment in the mining, quarrying, and construction and recycling industries. They are designed to crush a variety of materials to a specific size and shape, and offer a number of advantages over other types of crushing equipment. When selecting a roll crusher, it is important to consider factors such as the type and size of material being crushed, the desired product size, and the operating conditions of the crusher. Regular maintenance is essential for ensuring the long-term reliability and efficiency of the machine.

© 2023 Maxwell Crushtech. All rights reserved

Developed By India Online Business Solutions.